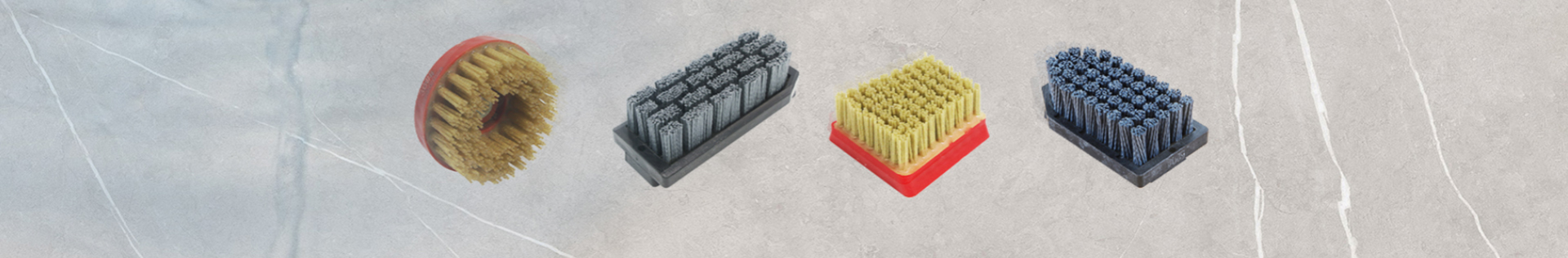

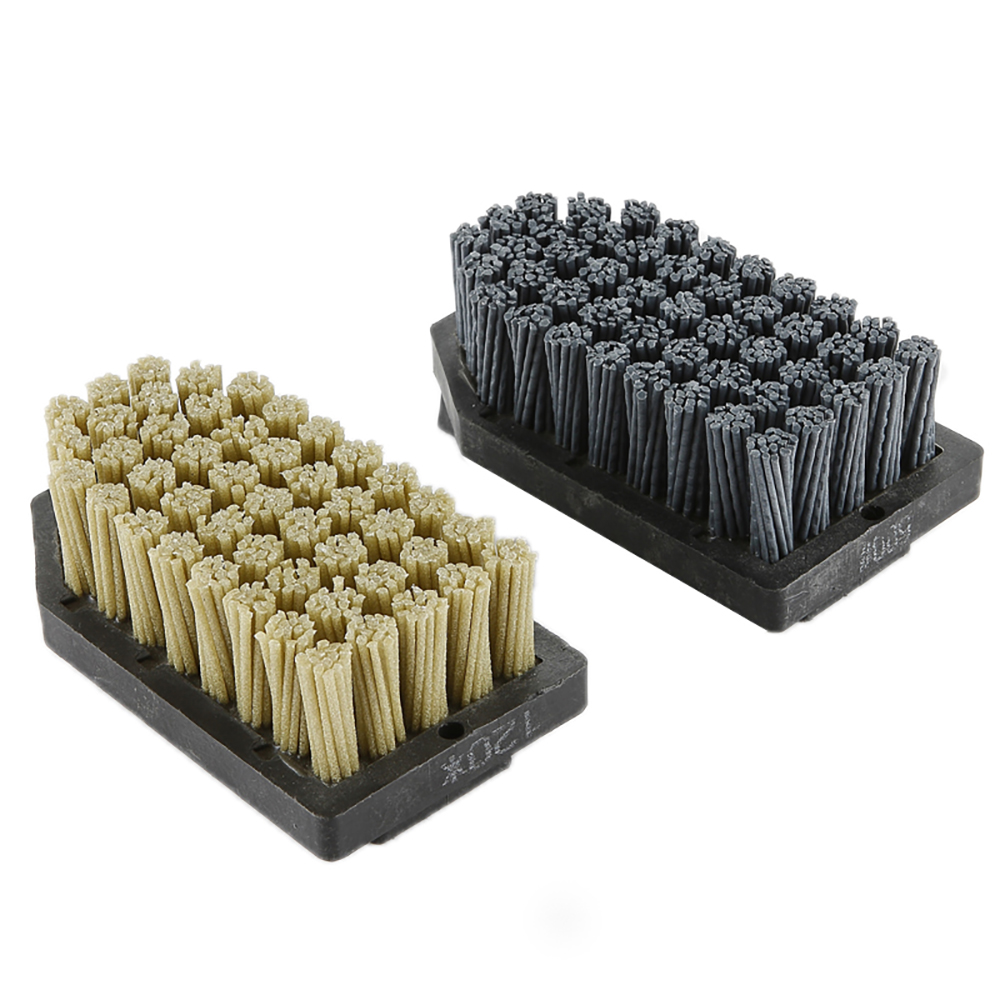

Joalo ka ha bohle re tseba hore ke abrasiveborashe ke lisebelisoa tse inehetseng bakeng sa mokhoa oa ho bentša majoe.Hangata li-brushes tsena li entsoe ka lisebelisoa tse senyang tse kang li-diamond bristles kapa silicon carbide bristles, tse thusang ka katleho ho tlosa likhahla, libaka tse boreleli le ho ntša khanya ea tlhaho ea lejoe.Li-brushes tsena li sebelisoa hangata lits'ebetsong tse joalo ka 'mabole, granite, le masela a li-countertop tsa quartz, polishing ea fatše, le ho lokisa holim'a majoe.

Bophelo ba tšebeletso eaborashe bo hlabange ka angoa ke lintlha tse 'maloa.Tse ling tsa lintlha tse ka sehloohong tse amang bophelo ba borashe ba abrasive nakong ea ts'ebetso li kenyelletsa:

1.Material Hardness: Ho thatafala ha lejoe le bentšoang ho ka ama haholo bophelo ba ts'ebeletso ea borashe ea abrasive.Majoe a thata a kang granite kapa quartz a tla etsa hore borashe ba hao ba tabohe ho feta majoe a bonolo a kang 'mabole.

2.Khatello e sebelisitsoeng: Bongata ba khatello e sebelisoang ha u sebelisa borashe ea abrasive bo tla ama nako ea bophelo ba eona.Khatello e feteletseng e tla etsa hore bristles e tsohe ka potlako, ho fokotsa nako ea bophelo.

3.Ho senyeha ha lejoe: Lejoe le nang le lejoe le phahameng le tla etsa hore bristles ea borashe ea hau e fokotsehe ka potlako.

4.Lebelo le ho bilika: Lebelo le ho bilika moo ho sebelisoang borashe bo hlabang le hona ho tla ama nako ea bophelo ba eona.Lebelo le phahameng kapa ho potoloha ho feteletseng ho tla potlakisa ho roala ha bristle.

5.Tlhoekiso le Tlhokomelo: Tlhoekiso e nepahetseng le tlhokomelo ea borashe bo hlabang ke ea bohlokoa bophelong ba bona bo bolelele.Ho hloekisa liborashe tsa hau khafetsa le ho tlosa litšila le grout buildup ho tla thusa ho boloka ts'ebetso ea tsona le ho lelefatsa bophelo ba tsona.

6.Boleng ba borashe: Boleng ba borashe ba abrasive le bona bo ama bophelo ba bona ba ts'ebeletso.Li-brushes tsa boleng bo holimo tse entsoeng ka thepa e tšoarellang le mekhoa e tsoetseng pele ea ho etsa li na le ho tšoarella nako e telele ho feta borashe ba boleng bo tlase.Ke habohlokoa ho hlokomela hore bophelo ba ts'ebeletso ea li-brushes tse senyang bo ka fapana ho itšetlehile ka maemo a itseng a tšebeliso le boleng ba borashe.Ho hlahloba khafetsa le ho nkela borashe ba khale sebaka ho tla thusa ho boloka tšebetso e ntle ea ho bentša.

7.Wlitsebo le boiphihlelo ba li-orkers le tsona li tla ama bophelo ba ts'ebeletso ea borashe ba abrasive.

Mokhoa o Nepahetseng: Mosebeletsi ea hloahloa ea nang le boiphihlelo ba ho sebelisa borashe bo hlabang ho ka etsahala hore a sebelise mokhoa o nepahetseng.Sena se kenyelletsa ho sebelisa tekanyo e nepahetseng ea khatello, ho boloka lebelo le ho potoloha ho tsitsitseng, le ho sebelisa angle e nepahetseng.Mokhoa o nepahetseng o ka fokotsa ho khathala ho feteletseng ha borashe ba hau, ka hona, ho lelefatsa bophelo ba bona.

Ho ka 'na ha e-ba le lintlha tse ling tse amang nako ea bophelo ea borashe bo bosootho boo re bo siileng, ka kopo arolelana le rona, re leboha tlhokomelo ea hau.

Elaine: +86-13336414847(Whatsapp / Wechat),email:expert01@huirui-c.com

Alice: +86-13336448141(Whatsapp / Wechat),email:expert02@huirui-c.com

Re tla leka ka hohle ho u thusa le ho fihlela tlhoko ea hau.

Ka kopo hlokomela: Lintlha tsa ho ikopanya tse fanoeng ke tsa lipotso tsa mecha ea litaba 'me li reretsoe baqolotsi ba litaba kapa batho ba batlang boitsebiso bo eketsehileng ka k'hamphani.

Nako ea poso: Aug-18-2023